Port Credit Marine Surveys & Yacht Delivery Society of Accredited Marine Surveyors  American Boat & Yacht Council  BoatUS®  Power & Sail Squadron

|

Sea Trials .. it ain't just a boat ride ! - Be aware that surveyors do not pilot boats on sea trial, they are there

to observe and report. I believe sea trials should be performed after survey, not before. Sometimes the survey will yield a number of clues that may not be wholly defineable unless the system or structure in question is put under load so doing the sea trial afterwards gives you a chance to follow up on those clues. The fewer people onboard the better. I do not want to have to ask someone to move every time I turn around. If you want to take along your buddies and have a few beers .... I can give you the names of a few other surveyors. |

|

| My surveyor friends in the southern states

tell me they almost always attend at sea

trial but for some reason it is quite rare

for marine surveyors in Ontario to be hired

for this purpose. Should you hire the surveyor

or mechanic for the sea trial ? You have

already spent a lot of money on a haulout,

power wash, survey and perhaps an engine

survey that cost bewteen $300 and $2000.

To now pay a surveyor and a mechanic to go

for a boat ride may seem a bit much. It all

comes down to your own expertise and your

tolerance for cost versus risk. Risk is assessed very differently by the

guy spending $15k on a 27' sailboat and the

guy dropping $850k for a 60' motoryacht,

you probably fall somewhere in between. If you choose not to have the surveyor or mechanic attend sea trial, at least you will have the benefit of knowing any potential issues revealed by those inspections if they have been performed beforehand. If you can only afford to have one onboard, I'd recommend the mechanic. On a 35' sailboat you can push the shaft back and forth to see if there is play. On a 50' powerboat you'd need three people pushing and pulling on that 12' long, 2" diameter shaft and even then it might not reveal an issue that would be visible in a hard turn at cruising speed. Hairline fractures in the stringers may be cosmetic gelcoat issues or they may open up slightly in a full power turn suggesting a bigger issue. I have seen entire bulkheads moving in 3' waves while they appeared secure sitting at the dock. Various electrical systems may be fine at the dock but start tripping breakers after they warm up. Air conditioning may run on shorepower but the genny may stumble and stall under that kind of load. With or without the surveyor or mechanic onboard the sea trial procedure is the same. This is not your boat yet and I strongly recommend you let the broker/owner/owners representative take the boat out of the harbour and dock her on returning. The fewer people on board the better. I insist on all engine and steering gear hatches being open for full access underway as I am frequently going back and forth between engines, helm and running gear compartments. On a motor yacht this often means that the entire saloon floor and mattress in the aft berth are removed and stowed so kids onboard are out of the question. On most sailboats the companionway steps are removed so access to the cabins is not possible for anyone but me. Be at the helm when the boat is started and see that all gauges respond properly then walk to the stern and ensure that cooling water is flowing and that any smoke clears within a few seconds. Older diesels may not show clear exhaust until close to operating temperature and that does not necessarily indicate an issue. After the boat has settled in to idle make note (I take photos) of gauge needle positions. As the boat leaves the dock I am in the engine compartment listening to and watching things like fuel filters/lines, motor mounts, gear engagement, stuffing boxes, hoses, impeller pumps, exhaust systems. looking for leaking hoses, leaking exhaust, excessive movement of stuffing boxes, shaft vibration and anything else out of the ordinary. If the steering gear is in another compartment I'll pop in there and ensure that steering cable, quadrants, hydraulic hoses, tiller arms and or tie rods are secure and responding appropriately. By the time we are out of the harbour I'll be back at the helm and note (photograph) any changes to gauges and see that oil pressure, temperature, volt meter and tachometer are all doing what they are supposed to do. I number all the photos in my notes as they can quickly get out of order as I photograph every issue I find. I'll then ask that she be slowly throttled up until she is at full operating temperature and during this time I'll be back and forth between various compartments and the helm. If there are two helms, every note/photo will be dupicated at both helms. Once at full operating temperature I'll ask for a full throttle run for 5 minutes and again monitor systems and gauges during that time, noting anomalies. I often meet with resistance from sellers on full throttle runs but all I can do is ask, I can't give orders. If she can't handle full throttle for 5 minutes, something is wrong. I'll then ask that she be throttled back to cruising speed and again watch that the gauges change appropriately. While still at cruising speed we want to observe drive train and steering gear in hard over turns both to port and starboard. Next we want her brought to idle for a few minutes and again check that gauges respond as they should. Now we want 3/4 throttle in reverse while watching steering gear, drive train and motor mounts on a twin, this is done one at a time. If the vessel in question is a sailboat it's at this point that we raise all sails and inspect them as they go up, ensure they are sound and that all winches, clutches, furlers, cars and tracks are operable and in good order. The boat can now be cruised at idle and if there is a generator it will be fired up and all systems run, stove/water heater/air conditioning etc. So that's it for the big ticket items and we can get into the smaller systems. I always power up these systems at the dock during the survey but it is wise to re-check underway. All navigation systems including lights, chart plotter, radar, autopilot, depth sounder and radios along with DC refrigeration, cabin lights, vacuum heads, potable water systems and anything electrical should be tested underway. Once secured back on the dock we can test the windlass and inspect ground tackle. PS. I wrote this article many years ago and things have changed a little. For the last 10 years Sharon has taken over all instrument monitoring and photography. . She also provides the helmsman with our list of actions in our specific order. This saves me a lot of rushing around between helm, steering gear and engine compartment. |

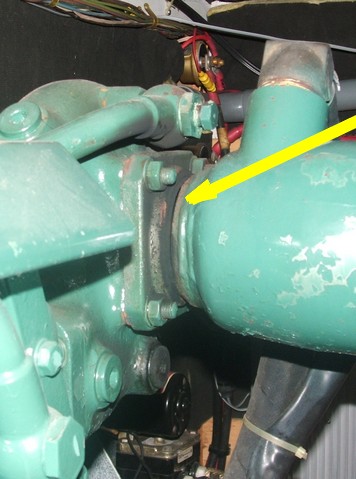

Motoryacht - all floorboards removed for duration of sea trial  Unsafe for kids, dogs and mothers-in-law  Froth at riser/manifold junction seen only at full throttle  Exhaust soot appeared only at full throttle |

|

| When I get around to it my next project will be to add a link here to a sea trial checklist in the meantime you might want to take a look at how Nordic Tugs do their pre-delivery factory sea trials and just for fun ...... Germanischer Lloyd Guide For Sea Trials of Motor Vessels | ||